Servo controlled solenoid valves

These solenoid valves are a combination of the pilot operated valves and the direct acting valves. The armature is mechanically connected to the diaphragm on which there is a pilot office. With minimal pressures the solenoid valve acts like a direct acting valve. Total opening as well as full flow do not occur at low pressures. With higher pressures it works as a pilot operated valve with full opening. Average response time 50 ÷ 500 ms.

Servo-controlled solenoid valves are mainly used for large orifice diameters starting from ½ inch. An overview of these valves can be found in our section solenoid valves for water.

- Servo controlled 3/4 "solenoid valves for steam

- Stainless steel solenoid valves servo-controlled

- Servo-controlled latching solenoid valves 1/4 "to 1/2"

Pilot operated solenoid valves

This solenoid valve uses the force of the fluid to operate the valve via a suitable integral pilot valve. The inlet pressure must always be at least the same as the minimum ΔP figure shown on the datasheets. Using the same coils as direct acting valves much higher fluid volumes and pressures can be controlled with this solenoid valve. Average response time 50 ÷ 500 ms.

Pilot operated solenoid valves offer the advantage of switching without differential pressure. These valves are available starting at 0 bar input pressure, with orifice diameters up to 1 inch. The standard brass valves are listed in the following categories:

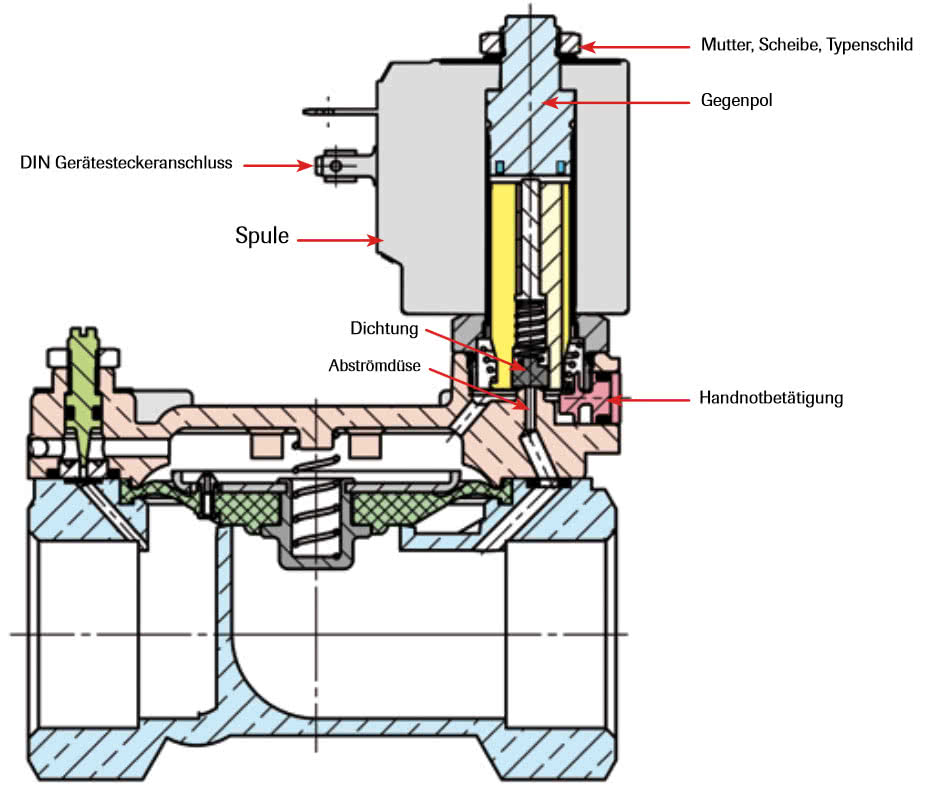

Direct operated solenoid valves

When energized the coil electrically generates a magnetic force attracting the armature towards the fixed core. Inside the armature is a seal that acts upon the main orifice, either when the coil is de-energised (normally closed) or when the coil is energised (normally open). By revealing the orifice allows the fluid to pass. Average response time 5 ÷ 25 ms.

Direct operated solenoid valves are preferably used in automation and with 1/8 "and 1/4" connections. In addition to standard valves, we also offer solenoid valves made of stainless steel, for hot water and steam, high-pressure valves up to 200bar, latching solenoid valves and versions for ATEX.

Installation

Check for the operating conditions on product label and on the technical documents.

Check for compatibility between medium and valve materials. In case of doubt, please contact the manufacturer. Keep the valve operator in a vertical position, facing upwards. This prevents limescale or dirt particles in the operator tube which

could restrict the armature or create excessive noise whilst operating. Whilst tightening or unscrewing the valve must be held or revolved only and exclusively by the hexagon or the frame set (in order to avoid damage to its components such as coil, armature tube, etc.).

For M&M International (Rotork) solenoid valves: The recommended tightening torque of the coil nut is 0,5 Nm maximum, a higher torque may cause damage to the valve armature tube. The recommended tightening torque of the connector screw is 0,5 Nm maximum, a higher torque may cause an excessive yield stress with consequent damages to the coil rivet and/or plastic encapsulation.

Connections

To ensure that the solenoid valve works properly, do not connect to pipework with an internal diameter less than the nominal diameter (DN) of the valve. Clean all pipework before connection to the solenoid valve: care should be taken to prevent foreign bodies – dirt or material chips – from entering the valve during the assembly phase. Use suitable seal material on the valve threads. Where liquid sealants are used, it is important to prevent them from entering the valve and block the movement.

Flow Direction

Respect the direction of flow across the valve, shown with an arrow or by numbers on the valve body, depending on the model type.

Filtration

If the fluid contains dirt particles it is necessary to install a filter upstream of the solenoid valve. Dirt is the most frequent cause of malfunction.

Environment

Coils fitted with suitable connectors have a protection class of IP65. However, it is advisable not to use the solenoid valve outside or in very damp conditions without adequate protection. Provide sufficient ventilation for the solenoid valve. During continuous service the coil of the solenoid valve becomes hot and should not be touched.

Solenoid valves with closing damping

Pilot operated solenoid valves (only versions specified in each datasheet) can be supplied with a system that regulates the closing speed of the diaphragm in order to control waterhammer.

The seal closing speed is operated by the adjusting screw: by screwing it clockwise (in the "+" direction) when using liquid, the valve will close slower reducing any waterhammer effect that may occur in the solenoid valve and the upstream pipes. In the case of larger valves (1 1/4", 1 1/2" and 2"), please adjust the anti-waterhammer screw to ensure that that valve closes as slowly as possible in order to avoid causing any damage that may affect the functioning of the equipment and valve due to the waterhammer effect.

The industrial solenoid valves are available in 2/2 normally closed, normally open and 3/2 way brass and stainless steel for water, air, oil and steam.