Header tank systems for filter cleaning systems

from 5" to 12"

Description

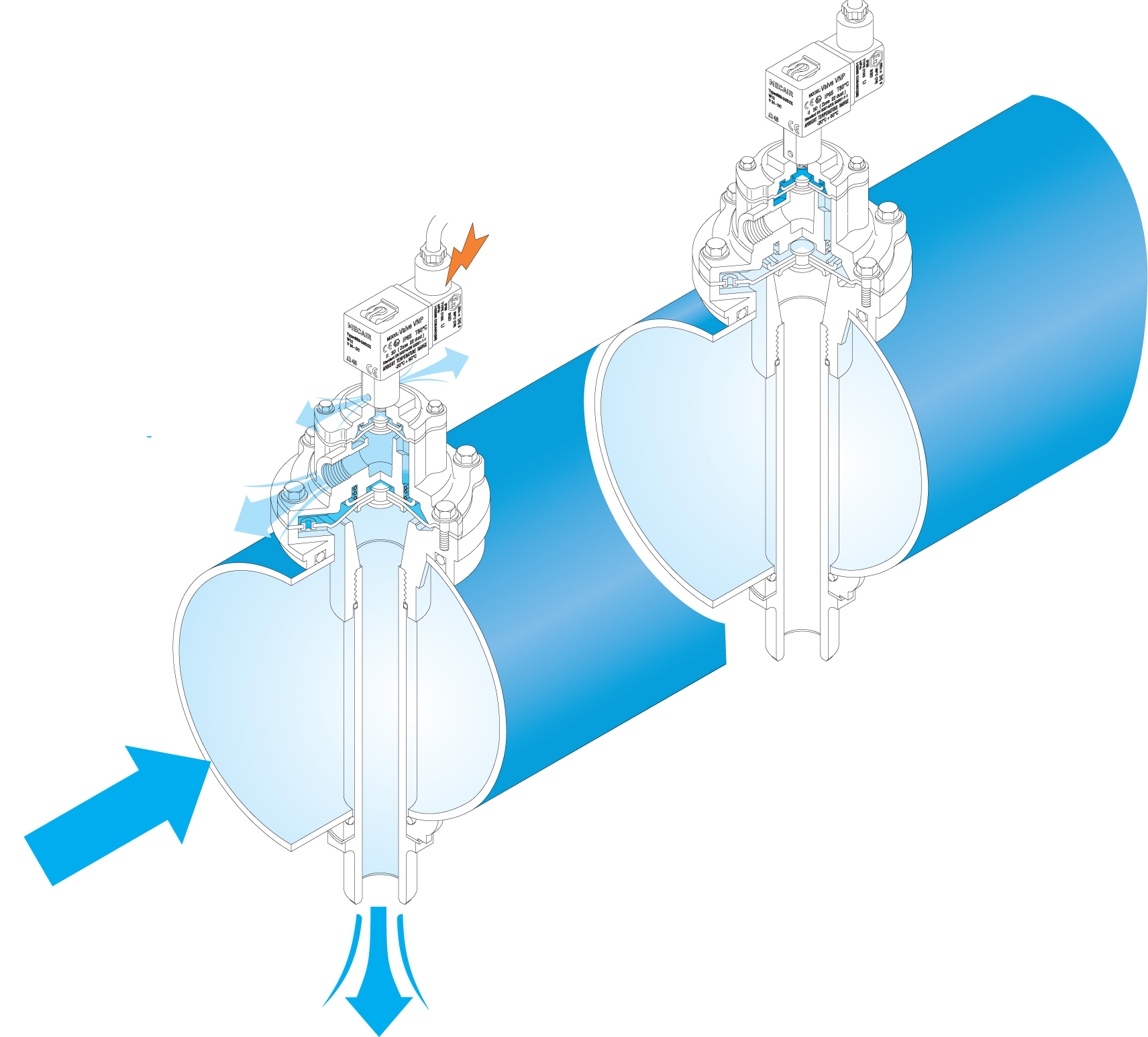

The "Full Immersion" systems, with the 500-series valves, consist of a round collecting tank with fully integrated pulse jet valves. These are suitable for dust collection filter applications, in particular for cleaning filter bags, cartridges, envelope filters, ceramic filters and sintered metal fibre filters.

The valve membrane of the 500-series has been specifically designed to be mounted onto a round header tank. The particular design of the 500 series of impulse diaphragm valves enables maximum flow and performance.

The tank system can be mounted directly on the filter, so that the overall system is optimized in terms of space and weight compared to traditional square systems.

The header tanks are manufactured according to the worldwide standard (CE PED or ASME certified) and are tested 100% before shipment.

In addition to the tanks as a system with pulse diaphragm valves of the 500-series, we also offer tank systems for valves for external assembly. The standard valves with threaded connection, pipe connection, manifold connection or flange connection can be installed at these versions.

The different versions are divided into types with an integrated magnet driven pilot valve and with external pneumatic control. The following tables provide an overview of the standard valves with threaded connections.

Pulse jet valves with integrated magnet driven pilot valve

If required, we can supply these valves with different socket connectors in protection class IP65. In addition to the standard connector, our offer includes, connectors with cables, connectors with LEDs (and cables), and LED seals for example.

Type

|

Port size Ø |

No. Diaph. |

min. pressure (bar) |

max. pressure (bar) |

KV

|

CV

|

|---|---|---|---|---|---|---|

VNP506

|

¾"

|

1

|

0.5

|

7.5

|

15.1

|

17.5

|

VNP508

|

1"

|

1

|

0.5

|

7.5

|

26.3

|

30.6

|

VNP512G

|

1½"

|

1

|

1

|

8.6

|

51

|

59

|

VNP514G

|

1½"

|

2

|

1

|

8.6

|

52

|

60

|

VNP562G

|

1½"

|

1

|

1

|

8.6

|

51

|

59

|

VNP564G

|

1½"

|

2

|

1

|

8.6

|

52

|

60

|

VNP516

|

2"

|

2

|

0.5

|

7.5

|

110

|

128

|

CA62MR

|

2½"

|

2

|

0.3

|

8.6

|

150.7

|

175.2

|

Specifications solenoid coils

The pulse jet valves with integrated pilot valve can be equipped with different solenoid coils. Special versions with ATEX certification are also possible.

Coil insulation

|

Class H

|

Voltage range

|

12 V DC (supply +10% max.) 18 W 24 V DC (supply +10% max.) 18 W 48 V DC (supply +10% max.) 18 W 110 V DC (supply +10% max.) 18 W 24 V 50/60Hz (supply +10% max.) 38/31 VA 48 V 50/60Hz (supply +10% max.) 41/32 VA 115 V 50/60Hz (supply +10% max.) 63/53 VA 220/240 V 50/60Hz (supply +10% max.) 46/37 VA |

Ambient temperature

|

−20°C - +60°C

|

Valves with external pneumatic control

Supplying a complete system, our compact pilot valve enclosures can be used for external control of the pulse diaphragm valves with pneumatic connection.

Type

|

Port size Ø |

No. Diaph. |

min. pressure (bar) |

max. pressure (bar) |

KV

|

CV

|

|---|---|---|---|---|---|---|

VEM506

|

¾"

|

1

|

0.5

|

7.5

|

15.1

|

17.5

|

VEM508

|

1"

|

1

|

0.5

|

7.5

|

26.3

|

30.6

|

VEM512G

|

1½"

|

1

|

1

|

8.6

|

51

|

59

|

VEM514G

|

1½"

|

2

|

1

|

8.6

|

52

|

60

|

VEM562G

|

1½"

|

1

|

1

|

8.6

|

51

|

59

|

VEM564G

|

1½"

|

2

|

1

|

8.6

|

52

|

60

|

VEM516

|

2"

|

2

|

0.5

|

7.5

|

110

|

128

|

RCA62MR

|

2½"

|

2

|

0.3

|

8.6

|

150.7

|

175.2

|